PVB Dispersions

POLYCOM is the only manufacturer in North America that recycles PVB into a water-based dispersion called EcoBlend. This unique solution can be used in multiple applications, such as adhesives, coatings, latex formulations, paint formulations, pre-coats, primers and more. EcoBlend helps customers incorporate upcycled materials into their products for post-consumer or post-industrial recycled content.

What Is PVB?

Polyvinyl Butyral (PVB) is a resin that was developed in 1927 and has many desirable performance characteristics, such as adhesion, binding, clarity, flexibility and toughness (see the bottom of the page for more properties).

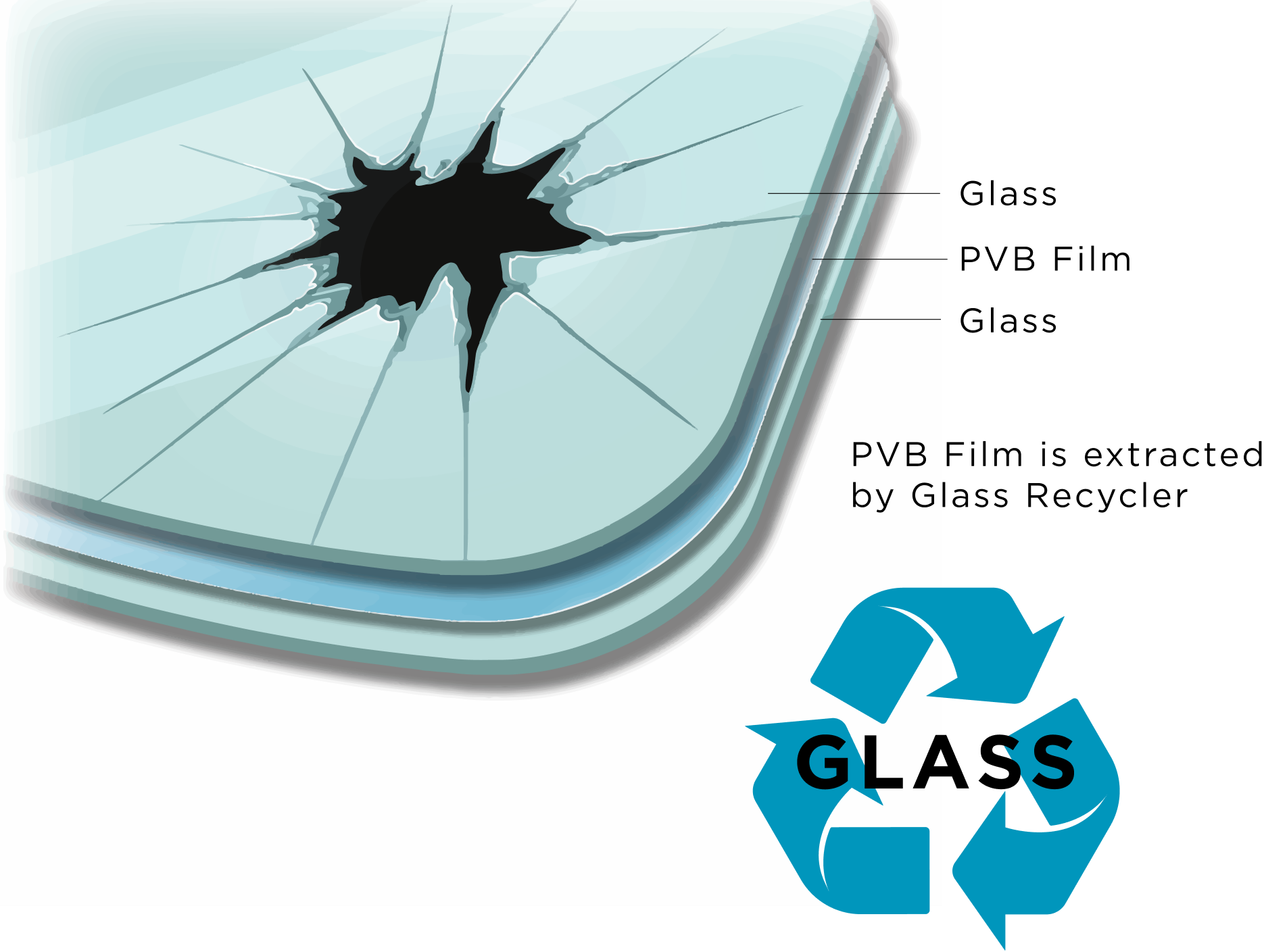

One of its main uses introduced in 1938 was a film used in laminated glass, such as the kind found in car windshields and safety glass. PVB film is sandwiched between layers of glass by applying heat and pressure, increasing its impact resistance and keeps the glass from completely shattering when broken.

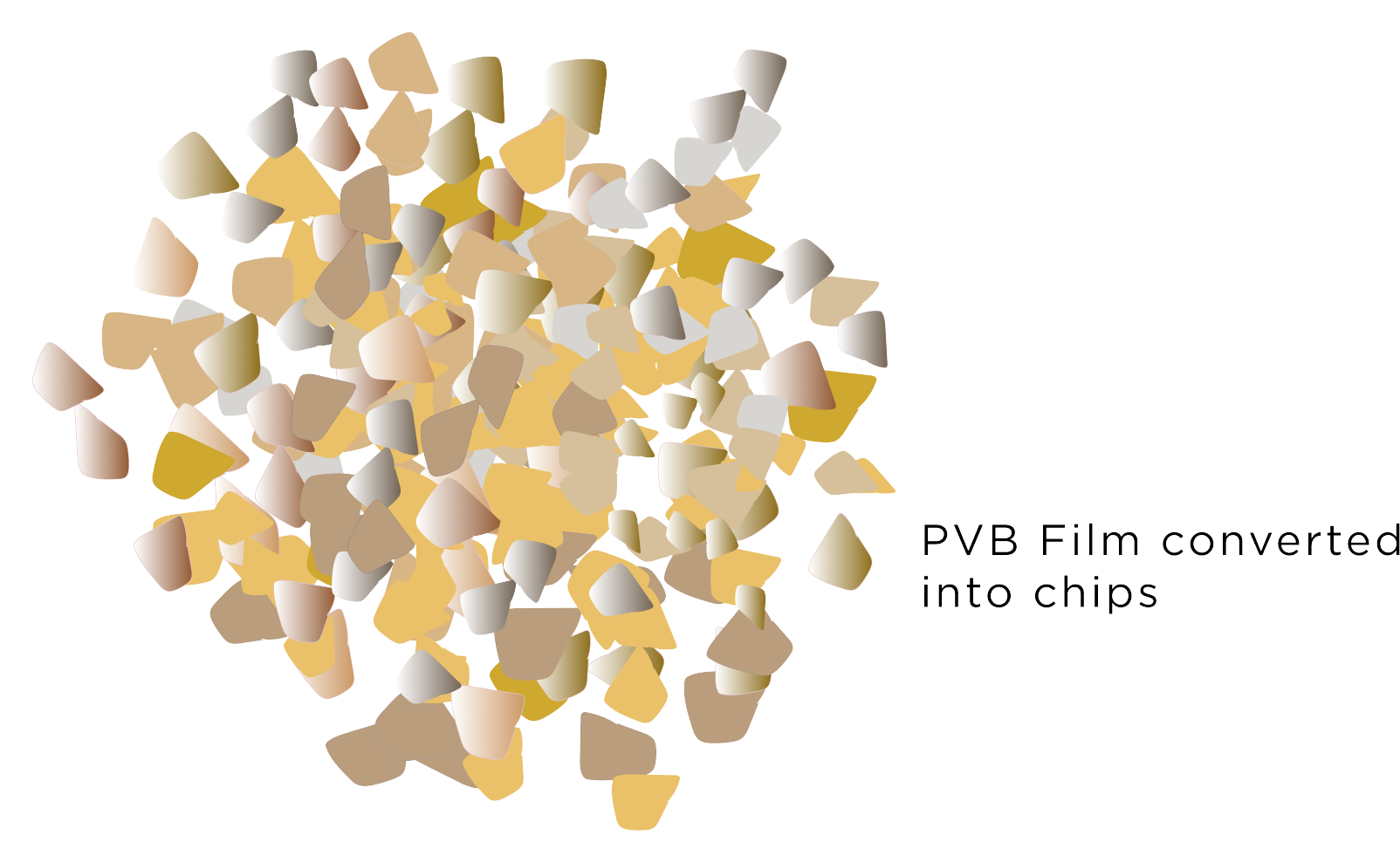

This PVB film is separated from the broken laminated glass and is recycled into chips or pellets that can be reclaimed, redirecting it from landfills.

Our EcoBlend Story…

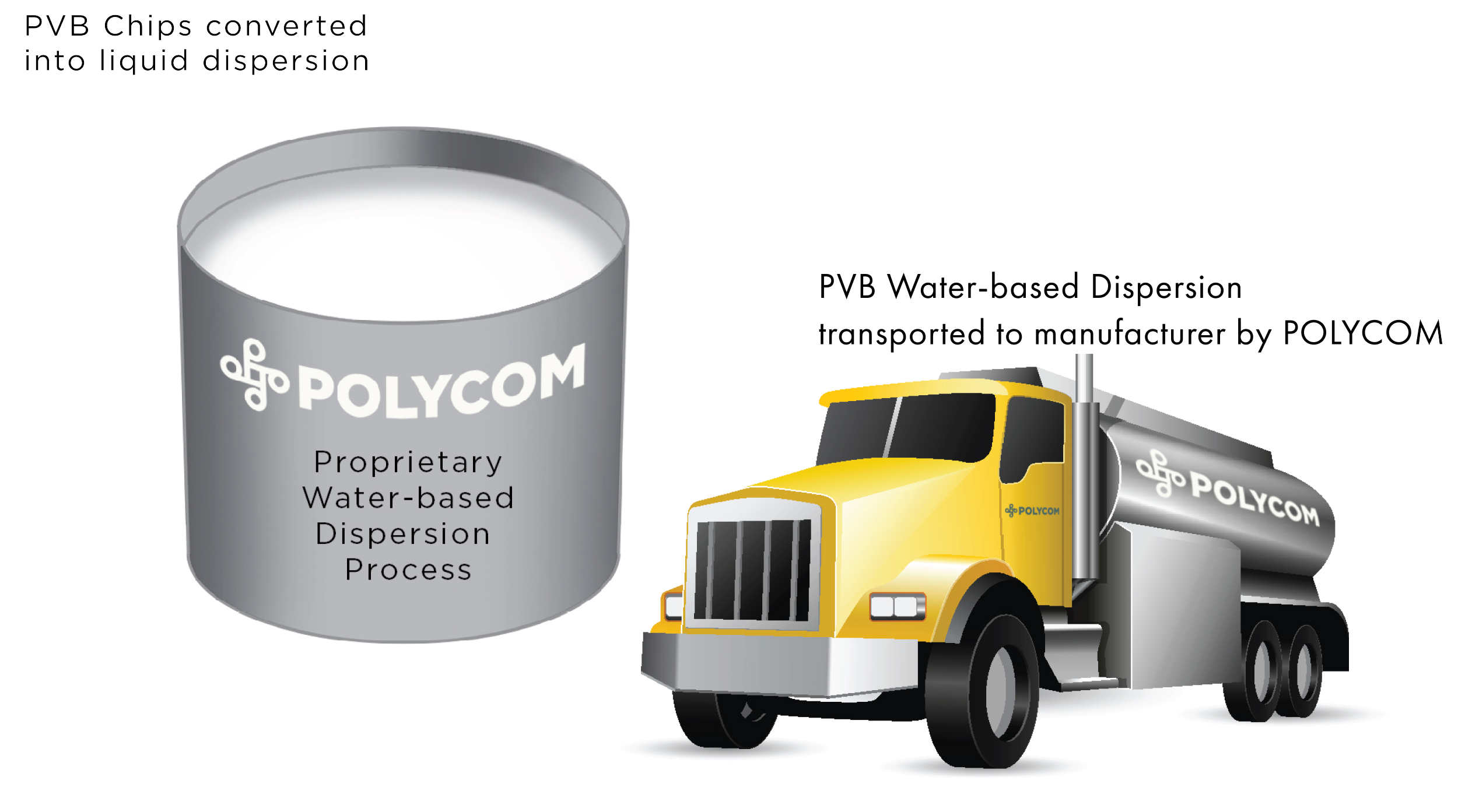

POLYCOM developed its proprietary process to upcycle PVB chips and pellets into a water-based dispersion we call EcoBlend, while keeping its inherent, desirable PVB characteristics. Products utilizing EcoBlend support our manufacturer partners’ claims of post-consumer and post-industrial benefits to their end-use customers.

POLYCOM can adjust its EcoBlend formulation to meet customer specifications, address specific needs, or achieve intended application efficiencies.

EcoBlend Applications

POLYCOM EcoBlend is ideal for a number of product assembly, binding, coating and protective applications for industries, such as:

- Automotive

- Construction/building materials

- Flooring assembly

- Furniture/office equipment

- Marine

- Merchandising/POS

- Modular homes

- Packaging

- Paints

- Product sampling

- Roofing systems

- Wall coverings

Examples

Adhesives/Binders

- Base polymer for adhesives

- Binder systems for entryway and decorative mats

- Pre-coat for woven carpet, marine and outdoor rugs, tufted commercial carpet and carpet tile, and exhibition carpets and rugs

Coatings

- Anti-skid for loose-lay LVT

- Anti-skid for non-woven carpet pad

- Floor primer for dust abatement

- Floor primer for non-skid installations

- Textile coating

other

- Artificial turf

- Luxury vinyl tiles and planks

- Moisture barrier for commercial broadloom

- Secondary backing for carpet tiles

PVB Properties

- Compatibility with other polymers

- Excellent film-forming properties

- Exceptional adhesion to a variety of substrates

- Maintains physical properties in thermoplastic processing

- Mechanical properties offer a highly elastic & tough film

- Robust service temperature (-40°F to 195°F)

- Unique optical properties

- Water resistance

EcoBlend Advantages

Environmental

- Landfill diversion (safety glass products – post-consumer and post-industrial waste)

- Low VOCs for better indoor air quality compliance

- Reduced resource and energy consumption & not contributing to raw material scarcity

- Solvent-free, water-based

- Supports your finished product’s environmental credentials

Other

- Custom solutions for specific coating or binding needs

- Highly UV Resistant